How 3D Printing is Revolutionizing the Fashion Industry

With its high precision, time-saving capabilities, and efficiency, 3D printing technology is transforming the global fashion industry.

What is 3D Printing Technology?

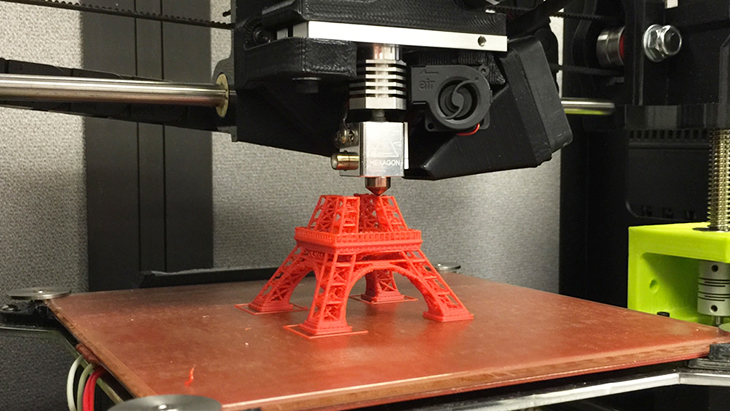

The concept of 3D printing may sound complex, but in simple terms, it is a manufacturing process that builds materials (plastic, metal, or any other substance) layer by layer to create a three-dimensional object. To illustrate, think of 3D printing as similar to the operation of CT scanners or magnetic resonance imaging (MRI) systems. These devices can scan and capture cross-sectional layers of any part of the human body. If you stack these layers together, you get a three-dimensional image of an organ or body part. This is analogous to how 3D printing technology operates.

Depending on the layering process and the construction of the 3D model, along with the constituent materials, 3D printing technology can be categorized into three main groups:

- 3D printing technology using flexible plastic and non-metallic materials.

- 3D printing technology using metallic materials.

- 3D printing technology using organic materials.

3D Printing Technology is Not New

Despite sounding unbelievable, 3D printing technology has been in development and practical use since the 1980s, pioneered by Charles Hull, the founder of the renowned 3D Systems Corporation. However, at that time, the cost to manufacture a 3D printer was exorbitant, around $100,000 to $400,000, impacting its affordability and widespread adoption.

After a period of rapid scientific and technological advancement, 3D printing gradually became more accessible and cost-effective. Nowadays, you can find numerous everyday items, such as children’s toys, machine components, phone cases, and dental prosthetics, produced using 3D printing technology at competitive and affordable prices.

3D Printing Transforms Fashion Design

With 3D printing technology, fashion designers can effortlessly create any shape or structure, including intricate patterns that might be challenging with traditional manufacturing methods. They have the flexibility to experiment with various designs and determine the best options for their collections.

Furthermore, 3D printing allows designers to quickly and easily make changes to their designs within 3D design software. According to fashion designer Iris van Herpen, in the near future, we could use 3D scanning devices and 3D printing technology to produce perfectly sized clothing for individuals in a short period. This could be the most impressive breakthrough that revolutionizes the fashion and accessory industry.

Prototyping for New Fashion Designs

Similar to the production processes in many other industries, prototypes are created before actual production begins. In fashion design, designers can use 3D modeling software and 3D printing technology to create clothing prototypes.

Whether using affordable 3D printers or large-scale industrial 3D printers, designers can efficiently and swiftly accomplish this task compared to traditional manual methods.

Instead of waiting for weeks or even months to create a prototype through traditional methods, fashion designers can generate a prototype within a few hours using 3D printing technology.

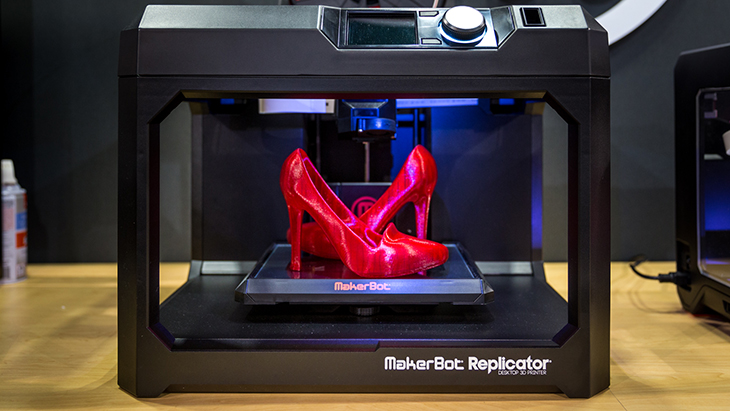

Creating Unique Accessories and Jewelry

Fashion designers can unleash their creativity by designing any kind of accessory or jewelry using 3D modeling software. This tool allows them to customize products, adjust details, and incorporate unique ideas during the design process.

Moreover, many designers now provide their 3D design files online for free, allowing anyone to download and 3D print them at home. Users can explore interesting fashion design patterns on various websites like Thingiverse, Myminifactory, Yeggi, and many others.

This enables customers to choose their favorite designs and print them using their preferred materials, whether it’s plastic, metal, or even ceramics.

Utilizing 3D Printing for Fabrics

Another fascinating area where 3D printing is applied in the fashion industry is in creating fabric. To 3D print fabric, users can employ three different methods: Chainmail, creating custom G-code, or using 3D modeling software.

In the Chainmail method, users simply need to download files from 3D printing websites and send them to their 3D printers.

With the G-code method, users can write their own code for the printer. This is one of the most effective methods if users have knowledge of coding and understand how 3D printing works, giving them full control over the printing process.

Using 3D modeling software, users can create a fabric structure from scratch and then 3D print it. However, users need to have an understanding of the 3D modeling process for this method.

Application for Pattern Making in Sewing Machines

In the textile and garment industry, 3D printing is utilized for pattern making in sewing machines.

The sewing machine operates based on the mold of the 3D-printed pattern to stitch fabric pieces together. This technology is often used to create made-to-order products or for custom order production.

3D-printed patterns can be rapidly and easily created, making them suitable for small-scale mass production. Additionally, they can be easily modified to produce different clothing styles or sizes.

The Future of Fashion: 3D Printing Revolutionizing the Industry

Imagine this: every week, instead of falling victim to the age-old (and often inaccurate) saying that ‘you have nothing to wear,’ you have access to an entirely new wardrobe tailored to your preferences, fitting your hobbies, and aligning with whatever plans you’ve made.

No, you don’t have to be an influencer receiving brand deals left and right; you’re simply in possession of a sustainable, personalized, adaptive fashion expert, and it’s believed to be the future of the clothing industry.

It’s quite simple. Using a collection of raw materials, you can print out your favorite designs on demand. When you need a new fit, you melt them down and start over. Gone are the days of ordering a pile of clothes online only to return them a few days later; now, from the comfort of your own home, you can update your style or follow the latest trends while minimizing waste.

Sounds like the ideal solution—and fundamentally innovative—for the exaggerated and harmful obsession, a concern that saw one in ten Brits admit to buying clothes ‘for the thrill’ last year.

As we continue to live on social media with #outfitoftheday dominating our timelines and celebrities constantly endorsing what’s hot and what’s not, this could also be an answer to the throwaway culture often associated with this.

Every second, the world discards a whole garbage truck of clothes, so if we continue to express ourselves this way, we really shouldn’t do it at the expense of our planet.

‘Disposable culture has deeply infiltrated the fashion industry. If a new spring collection launches, what happens to the old collection?’ Muhammed Shahadat of the NYC Fashion Technology Academy told Refinery29. ‘A 3D printer could be the only source for all of our shopping and recycling activities.’

Believe it or not, when I first learned about this concept, it sounded absurd, like it couldn’t possibly work. Yet, it addresses our urgent responsibility to discard single-use fashion for good. Yes, it undoubtedly reduces the waste of raw materials, but it can also significantly reduce the number of animals killed daily and lessen the harmful impact of the garment industry on local wildlife and surrounding communities.

Not to mention, according to a World Bank report, it takes 3,781 liters of water to make a pair of jeans—a massive amount that could be conserved. The benefits are apparent.

It’s all good and well, but how do we make this transition? Unfortunately, we’re not quite at the stage where we can all have a 3D printer. They typically retail for thousands of dollars and require relatively advanced computer skills.

An encouraging note, however, is that this technology is developing rapidly because, in reality, it doesn’t generate waste. Unlike traditional manufacturing (e.g., cutting and sewing), it can ultimately use recycled materials that we dispose of ourselves.

Providing us with the option to close the loop truly is a powerful idea. It’s also an excellent means to address the size discrepancies in clothing that have plagued shoppers for many years.

Shahadat explains: ‘It’s amazing to think that we can press a few buttons and produce a large amount of clothing for the world, especially for those in need.’ However, for 3D printing to become a fixture in everyone’s home, the moment has to come. When that time arrives, instead of buying clothes from stores, we could download digital files from retailers’ apps and then print out the garments at home.

If 3D printers can be democratized as Shahadat suggests, sustainable clothing will become the norm. However, the key to success is accessibility.

This brings us to convincing the fashion world that digitizing the production process won’t compromise authenticity—a not-so-easy task considering that when 3D-printed designs first hit the runway in 2010, they would break if the models even sat down.

Fortunately, the formulas to ensure their durability have improved tenfold, and we’re getting closer to overcoming this barrier. There’s still a long way to go before fashion achieves comprehensive sustainability, but the ability to download and print our own clothing is undoubtedly a step in the right direction.